Want to contribute to this article?

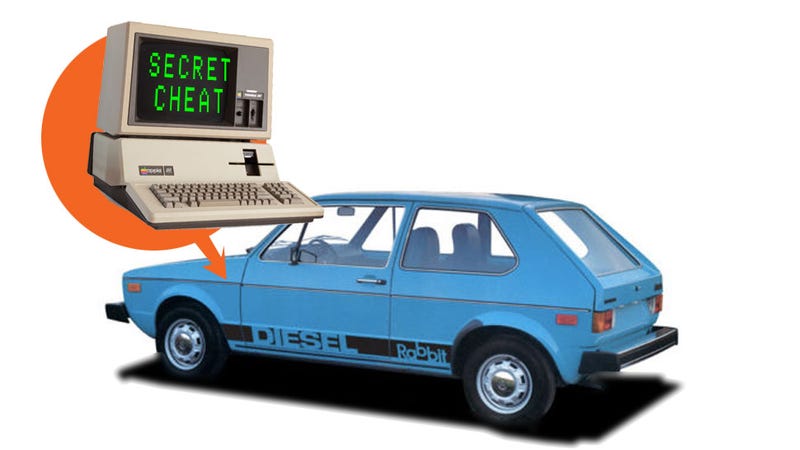

You might remember the Volkswagen emissions scandal several years ago. Volkswagen rigged thousands of diesel cars to achieve the legal NOx emissions benchmark only in testing - with the real 'out on the road' emissions numbers up to 40 times higher than in the lab.

The 'Dieselgate' scandal saw Volkswagen slapped with a $2.8 billion fine and got CEO Martin Winterkorn criminally indicted.

Now Mercedes have also been caught trying to intentionally sidestep automotive quality standards using 'defeat devices'.

Here's what the latest scandal means for the industry - and what Mercedes should have done.

What is a 'defeat device'?

Like every industry, automotive manufacturers and sellers have a duty to comply with quality standards and regulations imposed by national governments - for the good of employees, consumers or, as in this case, the environment.

Where Qualsys customers use software to work to and guarantee compliance, Mercedes have done the opposite: employing illegal software, or 'defeat devices', in their electronic control modules to mask true emission figures and create an illusion of compliance.

Defeat devices work something like this:

Having been caught using defeat devices, Daimler, Mercedes's parent company, have been ordered by the German Transport Ministry to recall 238,000 vehicles within German borders - and another 530,000 cars across Europe will also be recalled.

What does it mean?

Needless to say, the costs of such a comprehensive recall will be astronomical for Daimler.

This isn't counting any potential fines to be imposed, in Germany or elsewhere, the loss of senior personnel to potential criminal charges, or potential impact on sales - Volkswagen saw their branded sales fall for the first time in eleven years after the emissions scandal, with a 4.8% drop in 2015.

This latest emissions scandal comes after several smaller cases earlier this year, which saw BMW forced to recall 12,000 vehicles and Porsche recall around 60,000 vehicles.

In short, the message being sent to the automotive industry is clear - try and work around quality standards, and you will be caught and suffer the consequences.

What quality neglect does to your market cap - could Mercedes be next?

What should they have done?

Automotive standards like IATF 16949, APQP, VDA 6 and EPA emissions standards are there for a reason: to keep automotive businesses and supply chains profitable, efficient, properly managed, legal and compliant.

Mercedes might have stuck to these standards and avoided a large mess for themselves:

- VDA 6.1 covers areas such as recognition and minimising of product risk - like the production of engines with non-compliant emission levels, for instance.

- IATF 16949 prescribes integrated processes and evidence-based decision making - meaning the desired end goal of full emissions compliance should have been fed backward along the Mercedes supply chain to encourage production of compliant machinery.

- APQP techniques, used by General Motors, Chrysler and Ford, encourage long-term, up-front quality planning - no non-compliant cars would need to be fitted with defeat devices, because they weren't built in the first place.

The defeat device represents a forced, artificial mask of compliance at the final link of the chain - 'admitting defeat' and cheating rather than embracing quality standards.

Mercedes failed to plan and manage their quality proactively. The full consequences will be apparent in the coming weeks.

What to do next

Understand the VDA 6.3 automotive process audit standard with our introduction article.

Explore how GRC software supports genuine, business-wide automotive quality here.

And access our free automotive datasheets to find out why Qualsys is the partner of choice for automotive businesses across the globe.

Share your thoughts on this article